Development

Project planning

Manufacture

The objective of EPM-technology is to create all-inclusive concepts for various applications such as the electronics / electrical engineering, plastics and metals industries.

Contact

The company

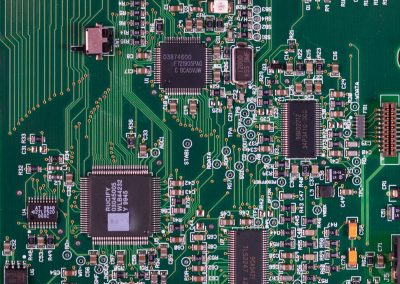

Electronics

Plastics

Metal

LED lighting

Electronics

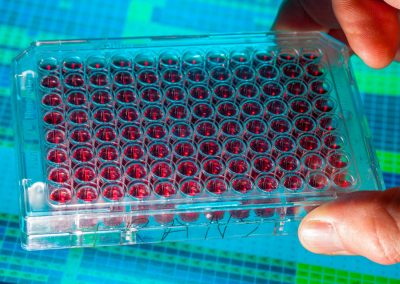

Testing technique / Adapters

We devise and develop innovative means of solving your specific problems by the application of advanced 3D CAD techniques.

As we manufacture the equipment ourselves, there is a short feedback time to the production division. Any modifications requested by you will be dealt with flexibly and quickly.

Our specialties – for your benefit:

- filigree technique for very narrow construction areas

- high currents in very small spaces

- contacts are made in four-wire measuring technology

Spring contact pins

We offer all- inclusive technical systems – well thought out from the beginning right up to the final product.

This is why we produce our own spring contact pins.

For standard applications, we offer spring contact pins with a diameter of 0.5 and a max. length of 4.0 mm with various head shapes.

They are all available at short notice from our stock.

Have you been unable to find spring contact pins for your specific application?

Just enquire about our range.

We will be pleased to advise you on

• crimped cables

• teflon-coated insulating units

• high-current special pins

• bare-board test pins or on four-point resistance measurement

designed to suit your particular needs. Spring contact pins are available in various shapes and sizes.

Plastics

Prototypes

It is often necessary for development as well as the customer to have prototypes on demand in order to understand the true dimensions, functions or haptics.

For this purpose we produce cost-effective prototypes. Therefore we use special materials in order to understand mechanical loading.

Overview of the process

- FDM – Fused Deposition Modellng

- SLS – selective Lasersintern

- SLA – stereolithography

- Vacuum casting – small series

- SLM – selective laser-melting

- Die-cast – series parts

- Injection moulding – series parts

Plastics injection moulding

Perhaps you need finished parts or special plastic parts,

very small, precise, high quality items, or perhaps an insert-moulded plastic-metal combination …

As we design and produce our own plastic moulds, we are able to meet your wishes, apply your ideas and meet your product specifications.

Wires can be insert-moulded down to a min. diameter of 0.1, a size where the part and the sprue can hardly be distinguished.

Furthermore, miniature parts from polycarbonate are not a problem to us. We can produce single weights up to a maximum of 5 g. Inserts with ready-made cables can also be produced.

Metal

Turned parts

Perhaps you need very small, precisely manufactured metal parts

or plastic-metal combinations produced as completely assembled mounting parts?

We manufacture micro-mechanical and precision mechanical items with diameters between 0.2 and 350 mm. Small batches are as welcome as large ones.

Construction of jigs and fixtures, tool manufacture

For the realization of complex system solutions for your products in the area of clamping- and gripper technology.

Whether in plant-, tool-, or special machine construction.

Send us your project, we design and develop for you.

Industrial LED lighting

LED-light-technic for industrial application in from interior and exterior (terrain and street lighting, parking lot and path lighting, hall and garage lighting) (additionally office, corridor and conference lighting) to special lighting corresponding to customer demands.

Performance such as consultation on-site, stocktaking, photometry and lighting layout as well as sampling rounds up our offer.

The company

The objective of EPM-technology is to create all-inclusive concepts for various applications such as the electronics / electrical engineering, plastics and metals industries.

The strengths of several partners are combined in order to make use of a wide range of know-how and to achieve high quality.

Each partner brings in a wealth of knowledge and manufacturing experience to the benefit of the customer who is offered a complete service.

The customer receives a finished product

This overall concept can be broken down into development, project planning and manufacture.

The customer will benefit from many years experience in the automotive industry, in automation and process development.

We are able to offer in any of these fields exactly the type of support which is needed. The benefits for our customers include:

- One single contact person

- Many years’ experience in various fields such as development, project planning and manufacture

- No costs incurred until the order is placed

- Manufacture of finished parts and products

- Small or large production batches

- Final checks and tests

- Reduction of costs and time spent on purchasing

- On request items are packed ready for shipment and shipped